Hydrogen is a clean and powerful source of energy that has the potential to revolutionize the way we power our world. However, with this great promise comes great responsibility, as hydrogen poses significant safety risks that must be addressed. In this post, we will explore the risks associated with hydrogen and the mitigation strategies that can be implemented to ensure its safe use.

Understanding the Risks

The primary risks associated with hydrogen are its flammability and explosiveness. Hydrogen is a highly flammable gas that can ignite with just a small spark, making it a potential fire hazard. Additionally, hydrogen has a wide flammability range, meaning it can ignite at low concentrations in air and continue to burn until the hydrogen is depleted or the fuel source is extinguished.

Hydrogen is also highly explosive when it is mixed with air in the correct proportions. If a confined space is filled with hydrogen gas and an ignition source is introduced, an explosion can occur. Furthermore, the high pressure at which hydrogen is stored and transported can increase the likelihood of an explosion occurring in the event of a leak.

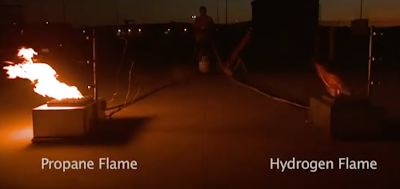

|

| Hydrogen vs. Propane Flame |

Mitigating the Risks

To ensure safe use of hydrogen, it is essential to implement strict safety protocols and appropriate mitigation strategies. These strategies include:

Equipment design: All hydrogen storage, transportation, and handling equipment should be designed and maintained to the highest safety standards. This includes using materials that are resistant to hydrogen embrittlement and ensuring that all equipment is regularly inspected and maintained.

Safety protocols: Strict safety protocols for hydrogen storage and handling must be implemented. This includes using leak detection systems to detect any hydrogen leaks and implementing emergency shutdown procedures in the event of a leak. All personnel who work with hydrogen should be trained on the potential risks associated with the gas and the proper safety procedures that need to be followed.

Ventilation: Ventilation is an essential element of any hydrogen safety plan. Ventilation systems can help to disperse any leaked hydrogen gas and prevent the formation of explosive mixtures. Additionally, hydrogen facilities should be designed with sufficient ventilation to ensure that any potential leaks are quickly dispersed reducing the risk of an explosion occurring.

Leak Detection and Alarm Systems: Leak detection and alarm systems are critical components of any hydrogen safety plan. These systems can detect hydrogen leaks and alert personnel to take appropriate action. Early detection of leaks can prevent the formation of explosive mixtures and help to minimize the risk of fire or explosion.

Pressure Relief Devices: Pressure relief devices are designed to release hydrogen from storage tanks and pipelines in the event of an overpressure situation. These devices can prevent the tank or pipeline from rupturing, which can lead to a catastrophic failure. Pressure relief devices should be designed and installed in accordance with industry standards and regulations.

Fire Protection Systems: Fire protection systems, including sprinklers and fire extinguishers, should be installed in hydrogen facilities. These systems can help to contain and extinguish fires quickly, minimizing damage and preventing the spread of flames.

Operator Training: Proper operator training is essential for the safe use of hydrogen. Operators should be trained on the proper handling, storage, and transport of hydrogen, as well as emergency response procedures in the event of a leak or fire.

Comments

Post a Comment